Transmission &

Distribution, Substations

-

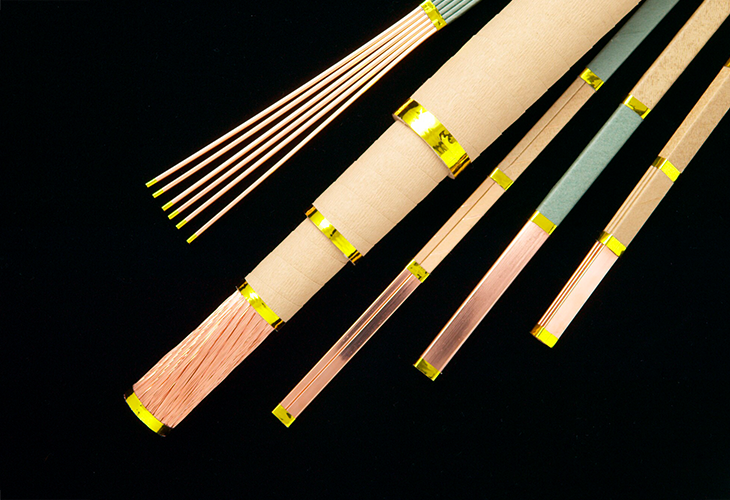

Continuously Transposed Conductors (CTC)

It is a product made by applying insulation

varnish to a cold-worked flat copper wire and winding multiple

strands of conductors, and then covering them with insulation

and other insulating materials.

By handling the conductor pre-winding process in our winding

production stage prior to the coil production process, we increase transformer productivity,

reduce load losses due to multiple potentials in the conductors, and reduce insulation paper usage after winding.

Contributing significantly to improved cooling efficiency.

-

Paper Insulated Wires

Insulation paper is wound around

each wire to improve the wire's durability against

moisture and other environmental factors.

-

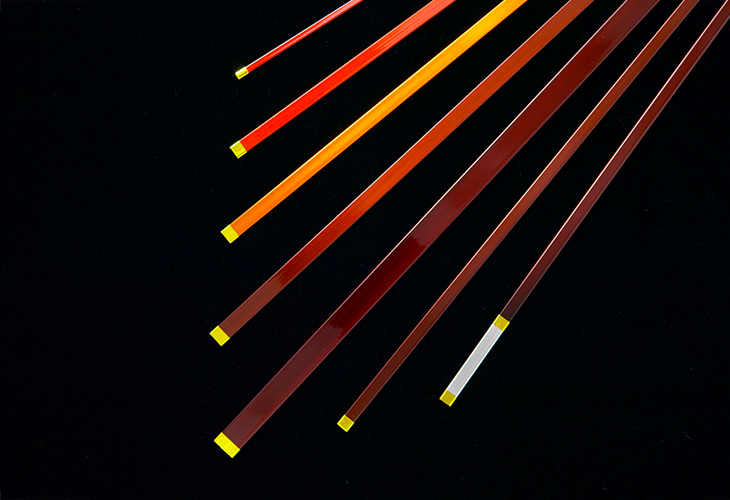

Enameled Rectangular Wires

The flat wires are coated with an insulation

varnish to prevent corona discharges that can occur during

transmission, distribution, and transformation.

-

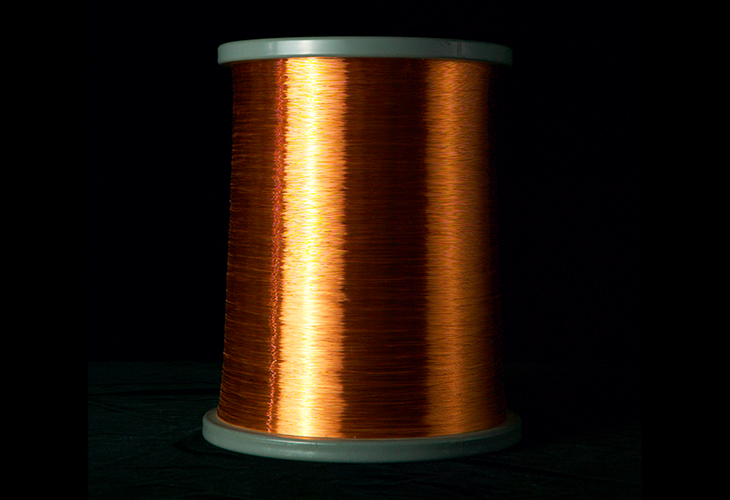

Magnet Wires

By coating the wire with insulation varnish,

the wire is durable enough to withstand high voltage and

high current to minimize power loss.